2G HTS Wire Specification

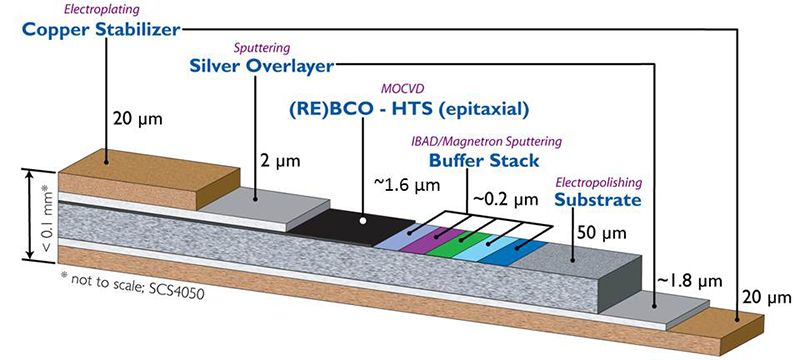

Basic information about our REBCO 2G HTS wires is given below.

Basic Specification

|

REBCO formula |

AP or HM |

|

Substrate thickness |

50 µm, or 30 µm |

|

Width |

12, 6, 4, 3, or 2 mm |

|

Piece length |

200 m to 500 m (up to more than 900 m), depending on spec |

|

Stabilizer |

Ag only – Type SF (Stabilizer Free), or Ag plus electroplated Cu – Type SCS (Surround Cu Stabilizer) |

|

Electroplated Cu stabilizer thickness |

10 µm to 110 µm total (5 µm to 55 µm per side) |

|

Critical current (essentially proportional to the width, determined using 1 µV/cm criterion via transport measurement) |

|

|

Ic (77K, self-field) |

120~160 A/4mm for AP tapes, 80~120 A/4mm for HM tapes |

|

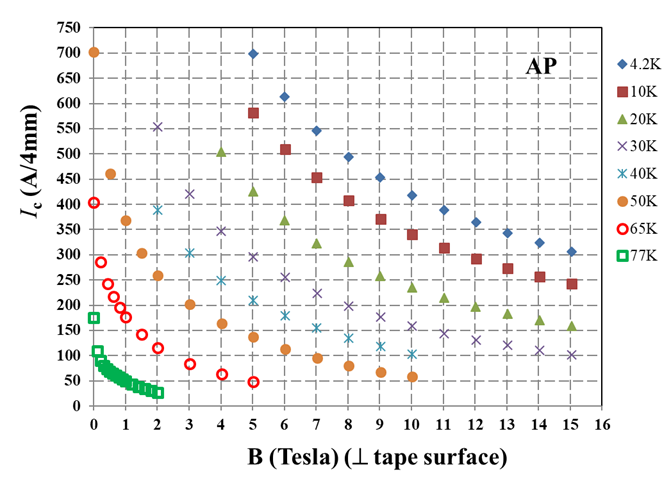

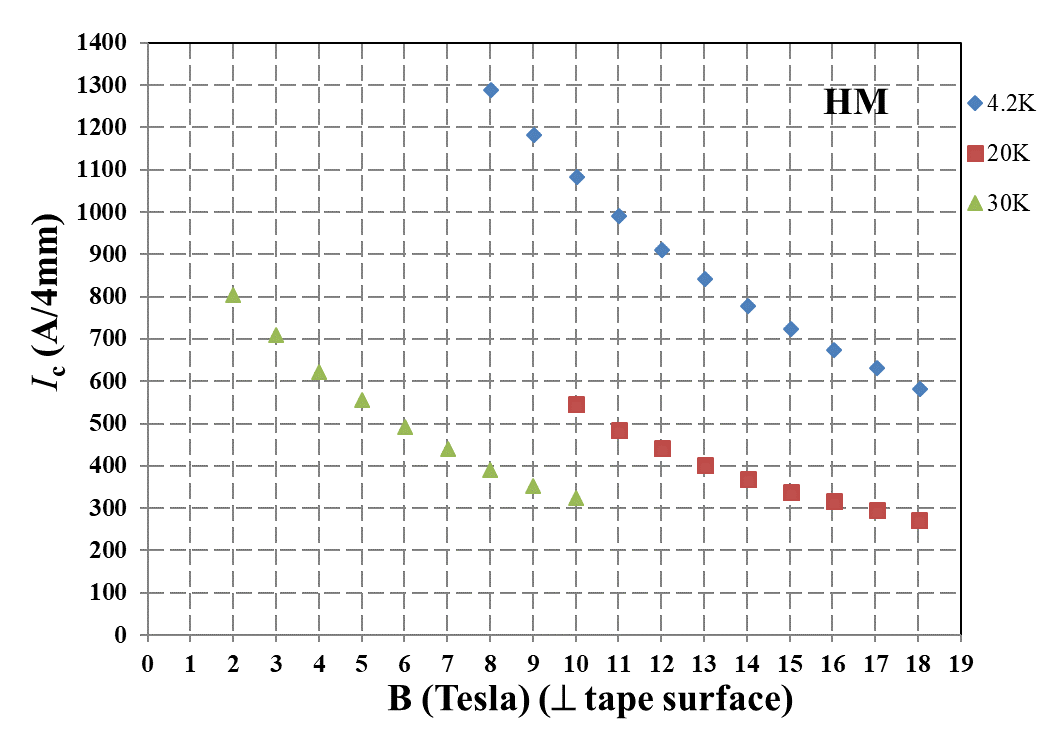

In-field critical current at various temperatures |

See graphs below for reference |

Mechanical properties

|

Axial tensile strength (at 77K, self-field, for 95% original Ic retention) |

Depending on substrate thickness and Cu stabilizer thickness (e.g., 550 MPa for tapes on 50 µm thick substrate with total 40 µm Cu stabilizer) |

|

Minimum bending diameter (at 77K, self-field, for 95% original Ic retention) |

11 mm for tapes on 50 µm thick substrate 6 mm for tapes on 30 µm thick substrate |

Other options

|

Joint |

Soldered lap joint, for Type SCS wires (joint resistivity ~ 50 nΩ-cm2 at 77K, for HTS facing HTS) |

|

Insulation |

Wrapped 25 µm thick polyimide tape (butt wrapping or 30% overlapping) |

|

Electroplated solder coating |

SnPb solder 5 µm to 10 µm per side on Type SCS tapes |

Fig. 1. Magnetic field dependence of critical current of a 4mm wide AP tape at various temperatures with the field in the direction perpendicular to the tape surface.

Fig. 2. Magnetic field dependence of critical current of a 4mm wide HM tape at various temperatures with the field in the direction perpendicular to the tape surface.